There are different waterproofing systems on the market and in this article you will learn about their advantages, disadvantages and their suitability for the execution of green roofs.

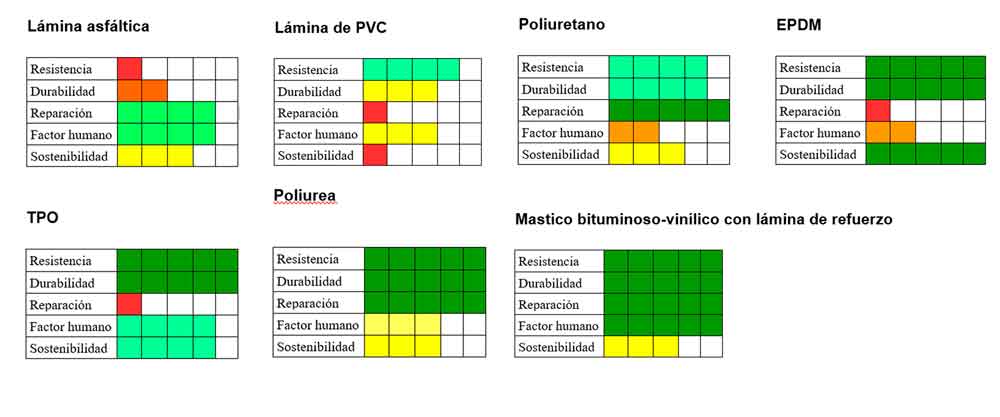

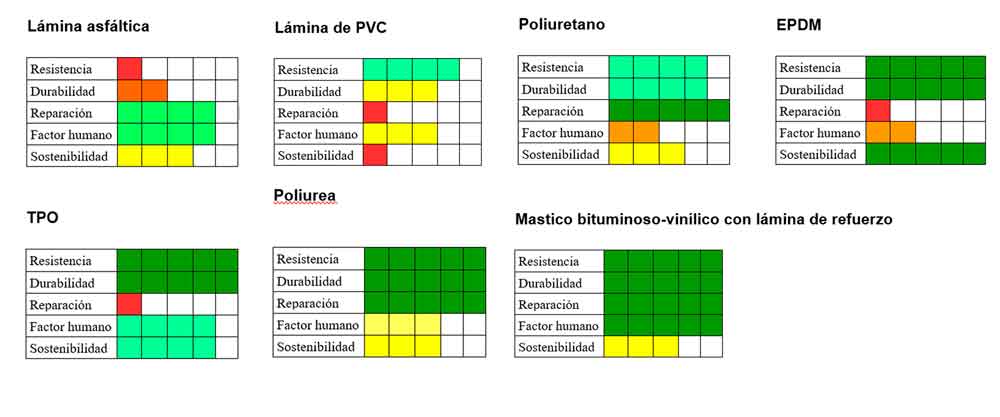

Over the years we can affirm that we have experience with the waterproofing of green roofs. To carry out the evaluation we are going to focus on five parameters: resistance, durability, repair, human factor and sustainability.

Parameters for assessing anti-root waterproofing for green roofs

Root resistance.

The waterproofing sheets for green roofs must be anti-root, which must guarantee this resistance by means of the chemical and physical stability of the material itself over time.

Durability.

Waterproof sheets for green roofs should provide a guarantee of at least 20 years of waterproofing, beyond what is currently required by regulations (10 years), as they will be continually subjected to attack by plant roots.

Repairs.

During construction work, accidents can occur that may puncture or damage the waterproofing from time to time. The ease of locating and repairing leaks is one of the characteristics that the waterproofing of a green roof should have.

Human factor.

A waterproof sheet may be perfect for a green roof, but if its installation, its thickness or the making of the joints depend on the human factor, the probability of error shoots up. A waterproofing for a green roof is better if it is less dependent on the human factor.

Sustainability.

In Singulargreen we understand sustainability as the optimisation of the consumption of resources and energy in the production of a building element taking into account its useful life and its recycling.

Waterproofing systems for green roofs

1. Asphalt sheeting, the best-known waterproofing system

Asphalt sheets are the most widely used waterproofing materials in Spain and are very easy to install.

The sheets are supplied in rolls and are applied using a blowtorch by melting the joints and adhering to the application base.

Within the family of asphalt sheets, the LBM(SBS)-50/G-FP polyester fibre reformed elastomer modified bitumen sheets with various reinforcement finishes are the ones used with anti-root resistance certification to make green roofs.

When designing a green roof with an asphalt sheet, what we must bear in mind is that the asphalt with which the sheet is composed becomes food for plant roots over time, destroying the integrity of the sheet .

To solve this problem, root repellent products are added to the sheeting. We do not know the long-term efficacy of these products and their chemical stability.

Generally speaking, a 10-year anti-root certification of an asphalt sheet is telling us that plant roots will not eat through the waterproofing in 10 years, but what happens in 20 years and 50 years?

From Singulargreen’s point of view, this type of waterproof sheet would not be recommended for green roofs in general and intensive gardening in particular. However, with less aggressive plants such as Sedum, it could have a greater durability, although it is not recommended.

2.PVC sheeting

PVC, polyvinyl chloride, in its basic state is a brittle and fragile substance that is of no practical use.

The secret to its conversion into waterproof sheets is in the recipe, as these are chemical substances that are mixed to obtain the desired properties such as: fillers, reinforcements, stabilisers, flame retardants, lubricants, fungicides, pigments, plasticisers, blowing agents, brighteners, impact modifiers, antioxidants, etc.

It is these products and their assembly that make the PVC film manufacturing process one of the most environmentally damaging, as many of them are toxic.

PVC sheets are marketed in rolls reinforced with fibreglass, the most common being 1.2 and 1.5mm thick and are applied using a hot air blower by fusing the edges of one sheet to the other .

Disadvantages:

- When over the years the components that accompany PVC lose their properties or disappear, PVC becomes the fragile material that it is by nature, it becomes brittle and can then be attacked by roots.

- When a PVC waterproofing reaches this point, it is difficult to repair, as it can no longer be welded or any other action can be carried out on it.

- On the other hand, PVC waterproofing installed as a floating sheet, i.e. not adhered to the substrate, means that any breakage that causes a leak is impossible to locate, as the water can move between the sheet and can appear on the roof far away from where the breakage has occurred.

From Singulargreen, this type of waterproof sheet could be recommended for green roofs due to its great anti-root capacity. However, from the point of view of sustainability, it would be the most polluting sheet on this list in terms of its manufacturing process.

3. Polyurethane

The liquid polyurethane membrane system is a product that once applied, polymerises, forming an elastic coating in the form of a layer adhered to the substrate, a continuous polyurethane membrane, without joints or overlaps, and completely waterproof and watertight.

The application can be carried out with spraying machinery or with a roller, in this sense it is an easy to apply and high performance system.

Polyurethane is more durable than other materials such as PVC and asphalt sheets, as long as the roof is well executed.

Advantages

- The high resistance

of polyurethane as a material. - Its adhered installation

which makes it possible to locate any potential leaks that may occur.

Disadvantages:

- Its resistant capacity depends on the state of the

depends on the state of the base substrate, in this sense if the substrate has projections

the polyurethane layer may be interrupted or reduced in thickness, resulting in spots where it will appear.

interrupted or reduced in thickness, thus creating points where leaks will appear more easily.

will appear more easily. - The anti-root

depends on the skill of the applicator to give 2 mm of thickness to the whole layer of paint.

the entire layer of paint, the applicator can always have a bad day.

At Singulargreen we do not recommend this type of waterproofing for green roofs either, due to the disadvantages mentioned above.

4. EPDM waterproofing

Technically, EPDM is polyethylene propylene diene diene monomer rubber, an elastomer with very good properties against the passage of water and atmospheric agents, with very high elasticity and resistance, which makes it a very suitable material for waterproofing all types of surfaces.

In addition, its mechanical resistance to roots and atmospheric agents gives it greater durability than the aforementioned materials. The brands that market it in Spain usually give a 20-year guarantee on the material and a 10-year guarantee on the installation.

From the point of view of the execution, the union between sheets must be done with a special adhesive, it is a delicate work and with probability of error. There are brands that supply EPDM in pre-welded blankets with a surface area of up to 900m2.

Disadvantages:

- Floating installation, because if a break occurs and a leak appears, the break would be visually impossible to locate, because the water may have moved between the slab and the waterproofing for several metres.

- It is important to be aware of the chemical incompatibilities of EPDM, as it cannot be in contact with water, chlorine or some asphalt products.

EPDM is the most environmentally friendly membrane in its manufacturing process, which is why it is one of the membranes we use at Singulargreen for the creation of green roofs.

5. TPO as waterproofing

This flexible thermoplastic polyolefin roofing membrane is manufactured by incorporating an ethylene-propylene rubber into a polypropylene matrix and is assembled by inserting a polyester mesh.

TPO is one of the latest films to make the leap into the construction market. It combines the strength of rubber with the heat weldability of a thermoplastic in a single sheet, with excellent lay-up characteristics.

Disadvantages:

- It still has the problem of floating installation that we have mentioned in EPDM and PVC and which makes it difficult to locate leaks in the sheet.

Regarding durability, the brands that market it offer, depending on the thickness, 10, 20 and up to 25 years of material guarantee and 10 years of installation guarantee.

TPO is not as sustainable in its manufacturing process as EPDM, but almost, so we could consider it a suitable sheet for installation on green roofs.

6. Polyurea

Polyurea is currently considered to be one of the best products on the market for waterproofing. There is a wide variety of polyureas depending on the applications and the properties we want to give it.

There are two types of polyurea, pure polyurea and hybrid polyurea. Pure polyurea has a greater capacity for elongation and resistance to abrasion. Within the pure polyureas there are two types; aliphatic or aromatic.

Pure aliphatic polyureas are the most expensive because they are resistant to UV radiation, while aromatic polyureas discolour and lose gloss when exposed to UV radiation and are stiffer than pure aliphatic polyureas.

Because of their resistance to UV exposure, aliphatic polyureas are best suited for application as a topcoat.

Polyurea can be applied by spraying or by hand application. Sprayed polyurea is normally sprayed hot by means of high pressure equipment and dries in only 3 to 4 seconds.

As it is a liquid component, it generates a thin layer that adheres to any irregular surface forming a continuous membrane. Hand-applied polyurea does not require spraying equipment.

It takes longer to dry as it is worked cold, forming a seamless, waterproof and elastic membrane in minutes, with high tensile strength and wear resistance.

Polyurea applicators guarantee the application of this material for up to 20 years, which is superior to previous waterproofing systems in terms of guarantee.

Advantages of this waterproofing

- It adapts as a single membrane to any irregular shape, remaining completely adhered.

- They have a high mechanical and chemical resistance

- Resistant to abrasion, compression, tearing.

- Any thickness can be obtained in a single application.

- Solvent free.

- Resistant to acid or alkaline media and various chemical agents.

- Applicable on any type of substrate.

- Anti-rooting.

Disadvantages:

- It is not a low carbon footprint product as EPDM can be.

- In the same way as polyurethane, although to a lesser extent, its correct application depends on the state of the base substrate, any edge or crack can lead to a reduction in thickness.

- A bad day for an applicator can lead to variable thicknesses and a decrease in the anti-root capacity.

From Singulargreen’s point of view, we consider polyurea to be a very suitable product for making green roofs due to its high performance and durability. However, at Singulargreen we do not use it due to its high dependence on the state of the base substrate and the skill of the applicator.

7. Green-Mastic

This waterproofing film consists of two layers of bituminous mastic with hot-applied vinyl resins sandwiched between two layers of reinforcing polyester film. Its formulation consists of vinyl resins, tar and inert minerals.

It is applied by heating the material and applying it with a trowel on the base substrate, forming a first layer of 4mm which remains completely adhered to the substrate, filling any cracks it may have. On top of this layer a reinforcement sheet is placed and a new 4mm layer of hot-applied mastic, sealing the solution with a polyester finishing sheet.

Advantages:

- Great adhesion on any type of substrate.

- Forms a continuous sheet without welds or overlaps, elastic and watertight.

- Re-joins when broken or perforated.

- Resists punching.

- Resists micro-organisms.

- It cannot be attacked by petrol or fuel oil

- Resists alkaline and acidic water

- Anti-rooting

However, the main advantage of this solution is the possibility of being able to apply it with guarantees on any type of support regardless of its state, i.e. it can be applied directly on the slab without the need for a regularising mortar finish.

At Singulargreen we offer this waterproofing in our green roof systems with a 25-year installation guarantee, the maximum guarantee on the market. Hot applied bituminous mastic as a reinforcement sheet is, from our point of view, the most recommendable waterproofing sheet for installation on green roofs.

The savings made in the preparation of the surface, as well as the safety it offers against breakage and installation, mean that we consider bituminous-vinyl mastic to be the best waterproofing alternative for green roofs.

We also offer online courses on green roofs. If you want to know more about green roofs do not hesitate to sign up.